DESIGN OF FLEXIBLE PAVEMENTS

Welcome

to Mbedule design centre

This is a specialized blog in Tanzania aimed at

generating various construction contents in engineering perspectives.

This post

it is basically aimed at giving guidelines to civil and highway engineering

students in the design of flexible pavements.

Why pavements should be designed?

The following are objectives of flexible pavement

designing. These are as follows

a). To provide a strong road which can overcome the

expected loading.

b). To minimize stresses which can affect the subgrade

in a particular area.

c). To ensure pavement layers do not fail seriously.

Pavement design is

the process of generating economical pavement layers which can work together

with natural soil to carry expected traffic in particular area. Flexible

pavement has various layers which are Subgrade, subbase, granular base, and

asphalt concrete surface.

Consider a following picture.

The image showing flexible pavement layers.

Pavement

design process

The following are main procedures or steps to

considered in designing flexible pavements. These are as follows.

i). Determining the amount of traffic in particular

area and the cumulative number of equivalent standard axles that expected to

pass to that road.

ii). Assessing subgrade strength where the road will

pass.

iii). Selecting suitable combination of pavement

layers.

How

t o determines Commulative number of Equivalent Standard Axle Loading (CESAL)

Before determining CESAL we need first to know what is

Vehicle Equivalent Factors. Equivalent factors are used to determining damaging

effect of Vehicles in comparison to standard axle (E80) load of 8 tonnes,

Equivalent factor is given by the following formula

Equivalent factor = (axle load in kg/8160)

^4

After

determining E80 of various vehicles we need to find proportion of E80 for

vehicle of 13 tonnes and above to the vehicles of less than 13 tonnes. Then if

the proportion of E80 of vehicle greater than 13 tonnes is equal or greater

than 50% to the total E80 of vehicles, then a road should be designed for heavy

vehicles otherwise should be designed for light vehicles.

How E80 can be described in damaging effect of

vehicles.

1. For example, an axle of 17 tonnes. By finding its

Equivalent factor in damaging effect.

Since an axle have 17 tonnes then,

Damaging effect by an axle=

(17/8.2) ^4 =18.47

This means that an axle of 17 tonnes when passes once

(1 pass) on a road have same effects as 18 passes of standard axle of 8.2

tonnes.

2. For example, an axle of 6.5 tonnes. Its equivalent

damaging effect will be as follows.

Since an axle have 6.5 tonnes then,

Damaging effect = (6.5/8.2) ^4 = 0.3948

Since is less than one, then take 1/0.3948=2.53

This means that 2.53 passes of 6.5 tonnes is equivalent to 8.2 tonnes of standard axle.

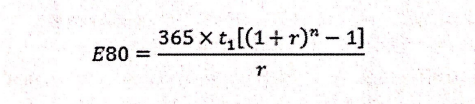

Commulative

number of Equivalent Standard Axle Load (CESAL)

This is typically E80 of number of years, or total E80

of years. It is determined by the following formula,

Where, t1

= average day to day number of standard axles in the year of traffic survey.

r

= Annul growth rate.

n

= calculated period in years.

For example, given design life is 20 years, growth

rate is 4.5% and average day to day number of standard axle is 760. Determine

CESAL.

Solution,

T1= 760

R=4.5%

N= 20

E80=

This os typically useful thanks author for that post

ReplyDeleteYes it is

DeleteThanks all of you

DeleteThanks

ReplyDeleteThere your are.

Delete